首页

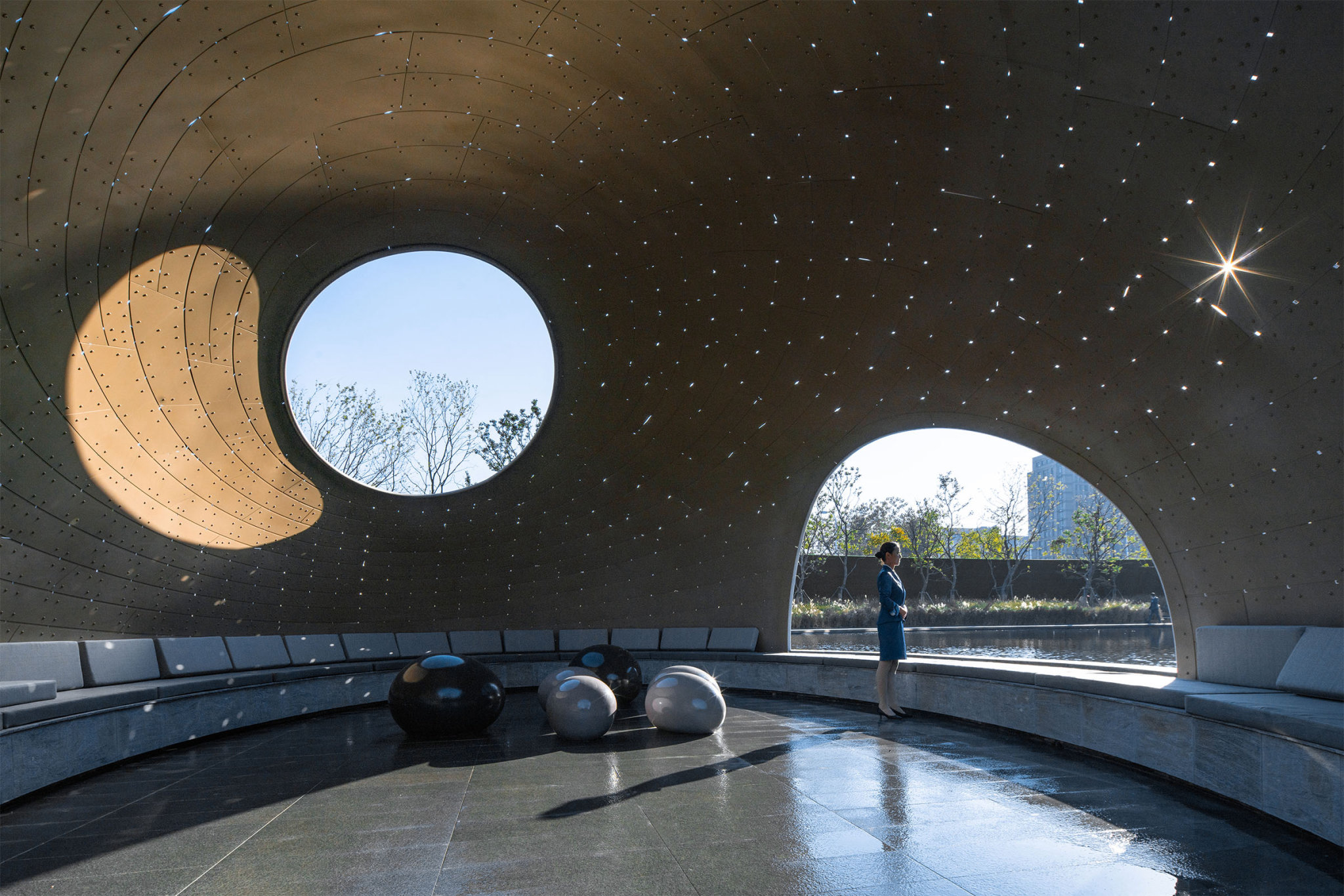

鸟巢水面薄壳景亭

Thin-shell Metal Woven Pavilion

结构表皮一体化的超薄壳体,结合向心式穹顶的纯粹体验,引导人觉知自己,回归内在平和。数字化设计结合数字化安装的一体化落地模式,为双曲面薄板的实现提供了品质保证。

项目全程引入了数字化设计与数字建造技术,我们专门编写了一套程序用以进行曲率分析和变形计算。将整个双曲面划分成了总计469片不同大小尺寸的条形曲面。而这些条形曲面通过编排设计,确保可以丝毫不变形地转化成现有设备容易加工的图纸。

项目整体实现了灵活可拆卸的装配式设计及建造,我们使用数字化技术,指导建造过程全部通过螺栓对位完成,规避了以往人工焊接导致的误差积累、薄板受热变形及建成后的不可移动性。每块材料均可随时替换,可整体拆移,某种程度上讲,它具备了时空上的永久性与延续性。

The ultra-thin shell with integrated structure and skin, combined with a centripetal dome design, aiming to guide individuals towards selfawareness and inner peace. The integrated mode of digital design combined with digital installation provides quality assurance for the realisation of the hyperbolic thin panel.

We have developed a dedicated program for curvature analysis and deformation calculation. The whole hyperboloid is divided into 469 strip surfaces with different sizes. And these strip surface, through parametric arrangements, ensure that no deformation of the transformation, and easier processing.

During the overall construction of the project, we have completely abandoned the traditional welding technique - instead, bolts are used for point-to-point fixing. This technique was used to complete the entire construction from the foundation to the main body. The advantage of this is that each bolt is digitally designed and endorsed to ensure the accuracy of the final form; thus avoiding the form-finding errors associated with the traditional manual welding process.